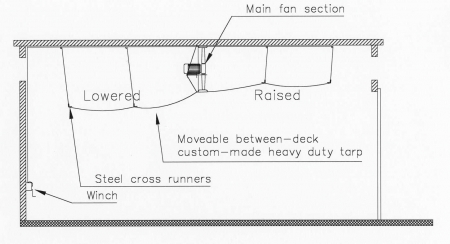

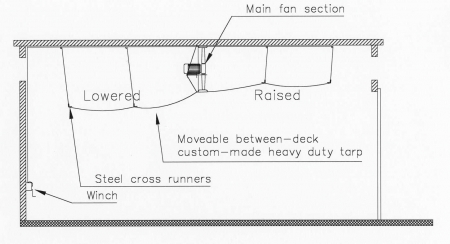

The moveable between-deck design was a Wooddryer System innovation in the 80's; however the design did not recieve the recognition it deserved due to initial engineering problems. The original installation had been too light in both tarp material and in the weight of the cross-runner design. In the early to mid 90's, kiln-direct and Wooddryer System revisited the idea and its logical design. After some re-engineering of all the components, we had found a much more efficient baffle system.

This moveable between-deck system has several advantages over the fixed between-deck designs, such as:

- Increases the air flow through the lumber in two ways:

First, it obviously prevents the air from going over the entire length of the lumber packs since it is a continual baffle. Second, by providing additional space above the between-deck, you will have less air flow resistance and turbulence; thereby making the fan system more efficient without costing additional energy.

- Flexibility is another key factor. Since the design is based on a heavy duty tarp material, which is flexible, the moveable between-deck adjusts to the potential uneven top of the lumber stacks.

- Durability, which comes mainly from the flexible material which has a tendency to bend instead of breaking if hit by a forklift or other machinery.

- Easy maintenance, if the tarp is torn in one way or another a simple tarp repair kit can be used instead of usually trying to return a metal sheet to its original form. Secondly, a relatively inexpensive tarp is easily replaced later onto the existing cross-runners.

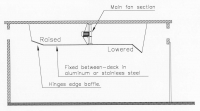

Fixed hinged baffle between deck. |

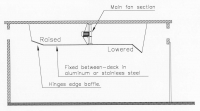

Fixed between deck with edge baffles. |

Material used for a fixed between-deck.

Kiln-direct suggests you use a non-ferious metal, such as aluminum or stainless steel. When using stainless steel you will not need thick plates, since stainless steel is much stronger than aluminum. In addition, stainless steel is easier to weld even though harder to cut/shear and bend, It will provide you with the best result for long time durability.

On older kilns and low economy budgets steel is used. Any steel usage in a lumber kiln has some major drawbacks and will require more maintenance than aluminum or stainless steel. Another serious drawback is the potential condensation which the steel can drip onto the lumber and discolor the surface. This is especially the case on oak, where the wood will turn nearly black from the reaction between the steel rust and the tanic-acid. Because of these reasons, steel in any lumber kiln should be coated every 2 years to avoid corrosion. On older kilns you can often see a steel between-deck become a safety hazard, either from falling items or from a person falling through when he or she is walking on top during maintenance visits.

Kiln-direct strongly recommends that you do not use plywood or other wood products for the between-deck for large kiln installations even though it may be installed with the idea of assisting a maintenance crew in performing their job. Wood products will deterioate in a lumber kiln, especially if the kiln has live steam spray for conditioning.

Operation of the baffles.

The edge type swing baffles are normally operated using a thin (3mm or 1/8") steel wire. By simply pulling the wire down to a hook, this keeps the baffles up during loading and unloading of the lumber kiln. When the kiln is loaded, the steel wire is taken off the hooks and the baffle is lowered onto the top of the lumber packs. This prevents the air from cheating over the lumber packs. In some instances, we have seen these operated using a small winch with several baffles on each. It should be mentioned that the edge type baffles normally consist of several individually operated plates. Each baffle plate is approximately 1.5-2.4 meter (5-8 feet) long.

A fixed dual baffle-deck is significantly heavier to operate than the edge type baffle. For this reason a winch is normally used to lower and raise the baffles. A common method is to turn a pipe (50mm/2inch) on the back side of the kiln using a motor or manual winch. Upon this pipe you attach the wires from each baffle. As the pipe is turned the wire is wraped onto or off the pipe thereby raising and lowering the edge of the baffles.

Special design notice on fixed dual baffle-deck.

It is important on both baffle systems that the baffles are sufficiently heavy to ensure that the baffle stays on the lumber. On the dual baffle-deck system, it is easier to design them too light. This will result in them being pulled up by the lifting force (push from below and vacuum on top) of the main fans. This is especially common if it is made using aluminum profiles and plates.